| Brand : | Baublies |

| Manager : | Arvin Yang |

| Phone : | 0755 - 8384 2073 |

| Fax : | 0755 - 8384 2050 |

| Email : | baublies@euro-me.com |

| Website : | www.baublies.com/en… |

FORMING TOOL

TASK:

<The mixing knife in Vorwerk‘s Thermomix combines the support disc and ground

blades with the M6 nut screwed on and fixed in place using the tumbling method. A sheet metal cap is to make the design food safe and dishwasher safe.

<Batch size 1.5 million pieces per year.

<No lubricant is to be used.

SOLUTION:

<A forming process with a flanging tool from Baublies suitably deforms the shee tmetal and fixes the machined parts: The sheet metal cap, which is flanged in two seconds, makes the design food-safe and dishwasher-safe.

<Forming rollers made of heat-treated tool steel.

TASK:

<Strengthening of axle journals for heavy commercial vehicles.

<Due to the high load, the transition from the bearing area to the end face of theaxle journal has high requirements for safety against cracking.

<The service life of the components is specified in at least 80,000 cycles.

SOLUTION:

<Deep rolling with single roll tool with base body

<Deep rolling process with forces of 5 kN

<Speed: 50m/min

<Feed rate 0,1 mm/rev

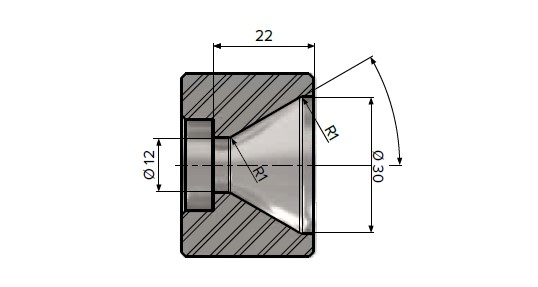

DIAMOND BURNISHING TOOL

TASK:

<Smoothing of a plasticizing unit/cylinder with an inner diameter Ø12 mm for injection molding machines. This creates a good flow rate of heated plastic.

<Challenge: There is high wear of the surface due to heat

<Material of the component: solid tempered steel.

SOLUTION:

<Baublies diamond burnishing tool for internal machining with base body suitable for hard surfaces HRC > 60

<with adapted diamond holder

<with smoothing diamonds form E

<with spring in tool body

<use on turning-milling center

<Machining: soft machining

– Speed VC 100 m/min

– Feed 0.07 mm/rev.

BALL BURNISHING TOOL

TASK:

<Burnishing of a forged ball pin with Ø20-35 mm.

<Large series: number of pieces from 300.000-500.000 pieces

<High demand on surface quality (Rz < 1μ) of the machined ball

<Noise should be avoided

SOLUTION:

<Adapted ball burnishing tool from Baublies with defined geometry(adapted angle).

<For use on lathes with driven tools.