| Brand : | M.CONTI |

| Manager : | Bill He |

| Phone : | 0755-8384 2048 |

| Fax : | 0755-8384 2051 |

| Email : | bill@euro-me.com |

| Website : | www.mconti.com |

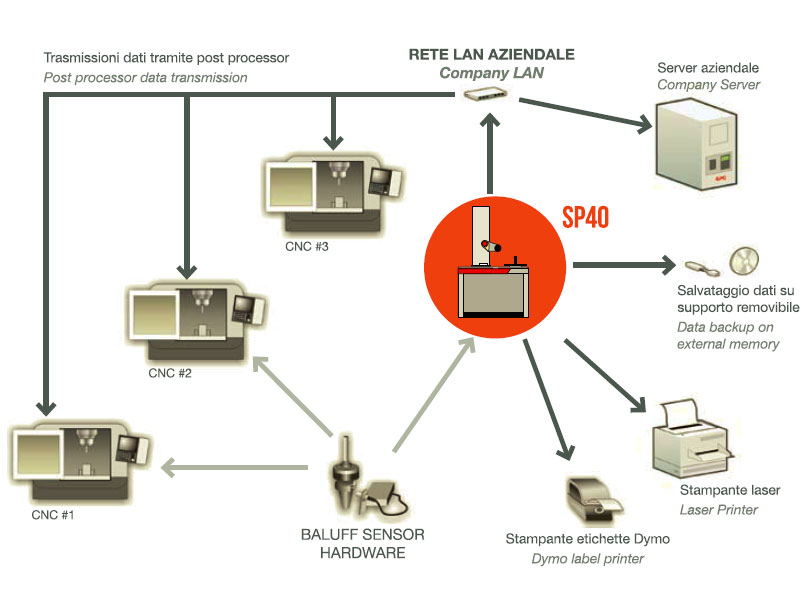

Line of presetters was created to supply a high performance instrument for an increasingly demanding market. Extreme precision and high performance for tools up to 1000mm high.

As always, in M.CONTI tradition, the Software Interface is easy and user friendly. Anyone will be able to check tool parameters easily and efficiently.

The Universal Blocking System is born out of years of presetting experience. It can guarantee maximum precision even with big dimension tools.

Fast and intuitive M.CONTI has managed to put in the SP40 high end performance along with ease of use that makes this the ideal presetter for everyone.

The high definition camera has micrometric precision, it captures profiles and tool geometry. The LED lighting system makes it also possible to view tool and insert surfaces with great clarity and crisp definition.

Designed and constructed with attention to detail, components and materials are of the highest quality and supersized to offer constant accuracy and precision for long years to come.